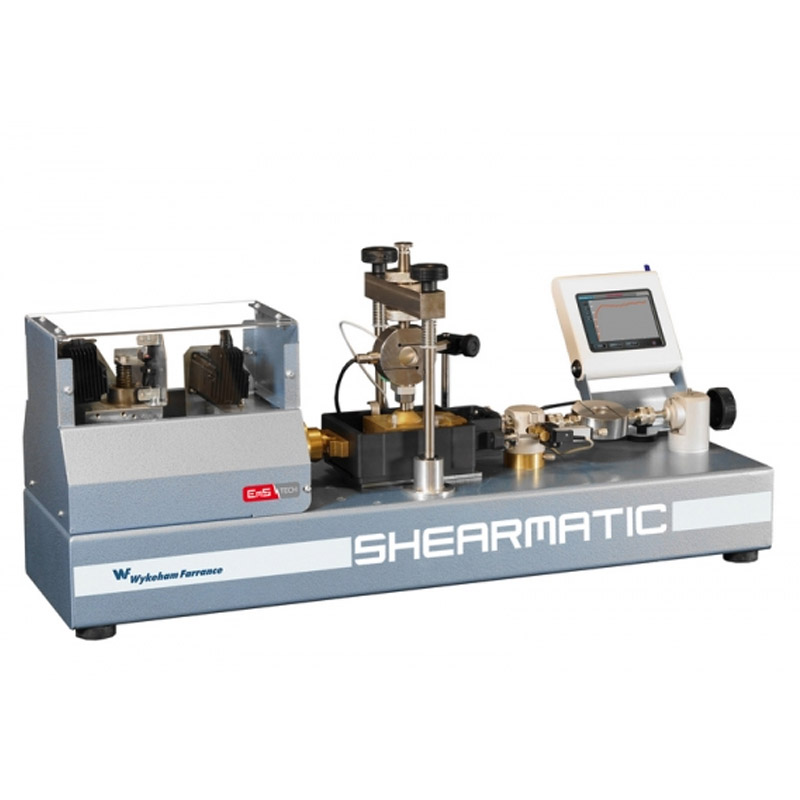

Automatic Shear Testing Machine

MAIN FEATURES

- Electromechanical servoactuation. Dead weights and air compressor are not required making the test easy and accurate

- User interface 6” touch screen colour display for numerical and graphical plotting of the readings

- Maximum vertical force: 10 kN

- Maximum horizontal force: 10 kN

- Two displacement transducers measuring vertical settlement and horizontal displacement

- Two load cells measuring vertical and horizontal force

- Vertical force load cell directly mounted on the loading tip assuring high accuracy of the readings and of the control signal

- Infinitely variable speed from 0.00001 to 15.00000 mm/min

- High stiffness load chain shear box – driving head – load cell

- USB pen drive for unlimited storage capacity and TXT format data output

- Optional PC control via LAN port and dedicated software

- Sturdy shear box techno-polymeric carriage untouchable by corrosion

- Test velocity and travel (forward and reverse) adjustable (residual shear test)

- Number of cycles adjustable from 1 to 99.

- Axial force steps can be applied instantaneously or as a ramp with programmable rate

- Also suitable for the oedometric consolidation using typical consolidation cells

- Specific and independent data recording for consolidation and failure stages

- Network ready for remote monitoring of the test status from PC, tablet or smartphone.

GENERAL DESCRIPTION

Shearmatic EmS is a standalone automatic machine with Electromechanic Servoactuation for direct/residual shear testing. It can also automatically perform the oedometric consolidation tests using the dedicated accessories. It incorporates two high-resolution stepper motors with high precision transmissions.

It features a closed loop PID control optimized for automatic test performance at the touch of a button, dead weights and air compressor are no more necessary.

The user interface is based on a large 6” touchscreen colour display permitting to start, pause and stop the test, to choose the data recording mode, to show the readings during the test execution and to carry out the transducers calibration.

The axial transmission of the horizontal force is accurately ensured by a straight connection between shear box, shaft and load cell. This design avoids the load measurement inaccuracies occurring with the widely used “swan neck” basic design.

A high quality techno-polymeric material has been adopted for the carriage of the shear box, offering excellent resistance to corrosion, wear and tear and to the chemicals often mixed with the soil specimens. Furthermore, this polymeric carriage is lightweight and easy to clean.

The digital controller reads and processes the vertical and horizontal forces and displacement readings and drives the motor accordingly for the proper automatic test execution under closed loop PID control.

The machine is supplied complete with the following transducers:

- 2 x 10 kN capacity load cells

- 11 mm displacement transducer

- 25 mm displacement transducer

In addition, a dedicated software (to be ordered separately) allows the remote control from a PC of multiple Shearmatic Ems machines. When the remote control mode is used, the PC software becomes the user interface and manages the main functions as well as the channels calibration by linear, polynomial and multi-coefficient curves.

The Shear box assemblies have to be selected and ordered separately.

The shear testing can also be performed with other traditional machines as:

- digital-shear-testing-machine,

- Direct and residual shear testing machine AUTOSHEAR,

- Large shear testing machine for 300×300 square samples

- Bromhead ring shear apparatus.